- TOP >

- ECOiON

To realize IoT and SDG's,

New water quality management

without any chemicals,

suitable for the coming era

The Ecoion makes agglomerates scale components in circulating water and drains them by an electrolytic reaction using unique electrodes.

It enables chemical-free and automatic water quality management, contributing to cost reduction and the global environment.

Also remote monitor and collect water quality data via WEB environment.

The Ecoion introduction clip

Check the mechanism of the Ecoion and the installation.

If you have the following issue with your cooling tower?

Wanted the energy saving of refrigerators and compressors

Wanted the energy saving of refrigerators and compressors Wanted to cut the chemical costs works and maintenance for water quality management.

Wanted to cut the chemical costs works and maintenance for water quality management. Wanted to solve the problems of scale, slime and corrosion from the ground up

Wanted to solve the problems of scale, slime and corrosion from the ground up Blowing water to maintain quality, Wanted to reduce the amount of water usage.

Blowing water to maintain quality, Wanted to reduce the amount of water usage. Wanted to check the water quality in real time, and to reduce access to the site

Wanted to check the water quality in real time, and to reduce access to the site

By the Ecoion, these issue will be solved

Installation image of Ecoion

Achieve -10% energy saving

by reducing energy loss

By introducing Ecoion, the quality of circulating water can be improved and automatically preserved. This reduces impurities such as scale and slime and maintain in heat-exchanger efficiency.

As a result, it also contributes to extending the life long of refrigerators and compressors

Inside the heat exchanger by the conventional management

Silica scale adheres and thermal efficiency decreases

Inside the heat exchanger after introducing Ecoion

Maintaining a healthy copper tube

No chemicals required! Enabling to control

water quality without chemical injection

Went to the site every month to replenish chemicals. analyzed and changed the amount and type of the chemical the next month.

Ecoion does not require any chemicals. Don't worry about chemcals replenishment, storage, and selection.

Since chemicals are not mixed in the blow drainage of the cooling tower, it can also contribute to global environmental conservation.

Comparison table Ecoion and Chemical

| ECOION | Conventional method (Chemical) |

|

|---|---|---|

| Emission of silica and inorganic salts |

Aggregates and settles and automatically drains to the outside of the system |

The concentration will increase because it is forcibly dissolved. |

| Occurrence of scale |  No scale |

"If the dissolution limit is exceeded, scale will occur. |

| With or without maintenance |  It only takes about 3 years to replace the electrodes. |

Chemicals should be infused once a month. |

| running cost |  Electricity bill only |

Needs chemicals + electricity bill |

It fundamentally solves the problems of scale, slime and

corrosion.

It would be unavoidable to have scale slime, and it was only possible to deal with it by symptomatic treatment (chemicals) that suppresses the speed of generation.

However, since the water quality itself is improved by introducing Ecoion, scale does not occur in the first place. As a result, the usual issues of cooling towers can be solved from the ground up.

Effect of suppressing bacterial growth

Before introduction |

After introduction |

Effect of suppressing corrosion

Before introduction |

After introduction |

Reducing blow down of cooling tower

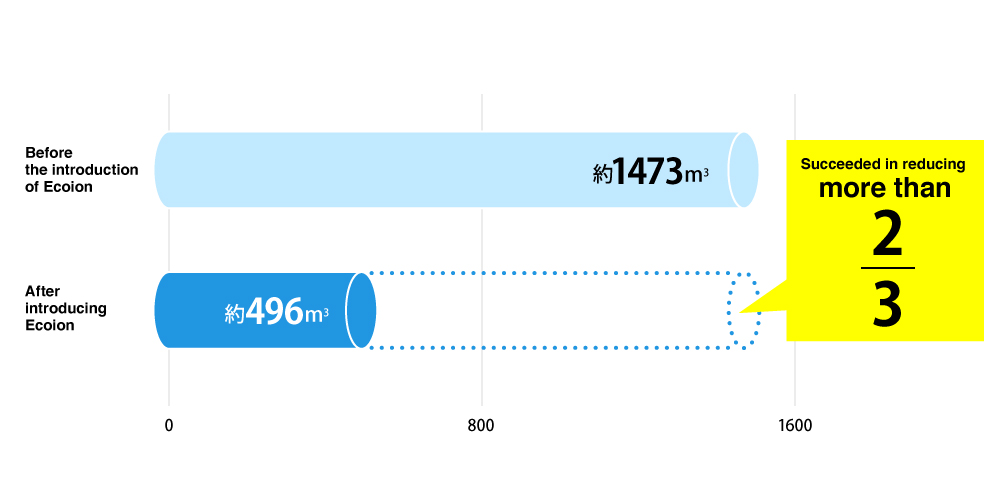

The water quality was controlled by blowing at a concentration multiple of about 3 times, However we succeeded in reducing the amount of water used by about 2/3 or more in one year by using Ecoion..

Changes in water usage (m³)

* The amount of reduction depends on the quality of make-up water and circulating water.

Enabling remote operation of

watar quality monitoring ※Option

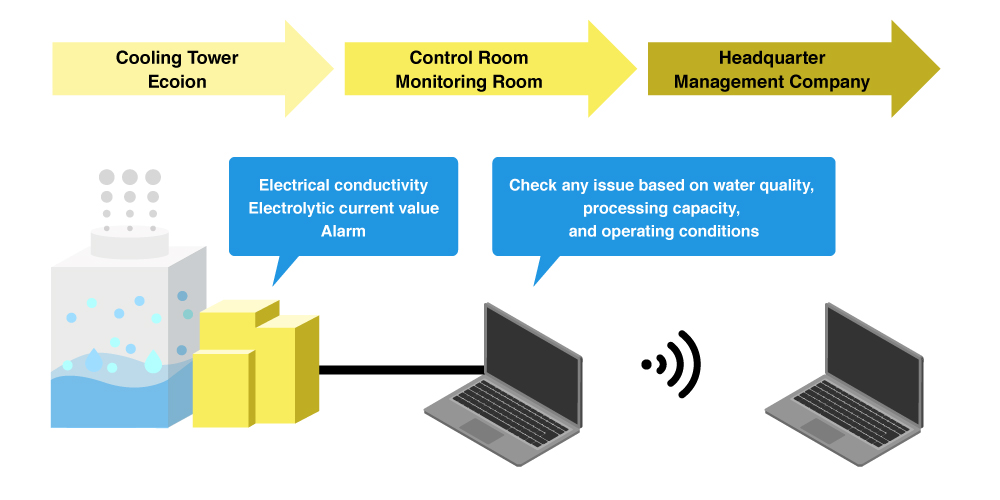

The daily electrical conductivity and electrolytic current are measured and transmitted to the control room.

This allows you to know the water quality in real time without on-site walk.

Even if you omit it, various alarms enable quick response in the event.

Furthermore, the data can be accumulated, it is easier to make plans such as changing the load factor.

Overview of Remote Monitoring

Installation Record

| Company | Watar | Cooling Tower | Cooling target | Issue |

|---|---|---|---|---|

| Medical device manufacturer | Well water | 117 t/h | Package cooler | Cost Reduction |

| Cold storage | City water | 150 t/h | Refrigerator | Cost Reduction, Energy Saving |

| Metal processing industry | City water | 60 t/h | Firing furnace | Slime, Chemical Insident |

| Heavy industry | City water | 129 t/h | Vacuum furnace | Scale adhesion |

| Steel industry | Industrial water | 200 t/h | Compressor | Corrosion, Rust water |

| Auto parts manufacturer | City water | 60 t/h | Reliability tester | Algae growth, clogging of circulation pipe |

| Auto parts manufacturer | Industrial water | 150 t/h | Electric furnace | Poor quality of make-up water (Indonesia) |

| Machine parts manufacturer | Industrial water | 150 t/h | Electric furnace | Poor quality of make-up water (Indonesia) |

| Milk maker | Industrial water | 250 t/h | Refrigerator | Scale adhesion and aiming chemical-free |

| Paper industry | Industrial water | 150 t/h | Equipment cooling | Scale adhesion, water saving |

| Cold storage | City water | 330 t/h | Refrigerator | Poor quality of make-up water in island |

*Excerpt

Specification

| Model number | ETS-300 |

|---|---|

| Circulation water volume | 200-300m³/h |

| Treated water volume | 15-20L/Min |

| Power-supply voltage | Three-phase 200V |

| power consumption | Up to 600W |

| size | W 1,146×D 715×H 1,103mm |

| weight | 90Kg |

| Operating weight | 350Kg |

| Price | US$ 38,000 ~ Excluding Duty, Installation, Transportation and Taxes |

Click here for inquiries

Please feel free to contact us

Contact us from WEB

| Contact us by phone | +81-(0)78-335-5581 |